GC History

This timeline outlines the development of Shimadzu's Gas Chromatography (GC) products over the past 150 years. Each entry reflects Shimadzu's commitment to advancing sensitivity, speed, and usability in analytical chemistry. From the introduction of the first GC system to the latest innovations, Shimadzu has made significant contributions to various fields, including pharmaceutical research, environmental analysis, and petrochemical testing.

Just four years after the invention of gas chromatography in 1952, Shimadzu developed the first gas chromatograph, leading to the series production of the GC-1A in 1957. Weighing 120 kg, the GC-1A was a giant compared to the more compact and versatile GC instruments that followed over the decades. This innovation initiated a continuous development process that remains active today.

Temperature programmable gas chromatography in combination with a fast cooling oven allows separation of complex samples in shorter time with better resolution. Another efficiency improvement is the patented dual-flow operation of two packed columns. Changes of column flow during the run of an oven temperature program are compensated by utilization of mass flow controllers. Additionally the integrator, C-1A supports the automated integration of gas chromatographic peaks and therefore evaluation of chromatograms.

The GC-8A marked a significant step forward by replacing asbestos with safer insulation materials. As one of the smallest GCs ever manufactured by Shimadzu, it combined performance with a compact footprint, making it popular for decades. The introduction of the auto sampler AOC-8A enabled automatic analysis of liquid samples in sequence, while the C-R4A integrator took over GC control functionalities, advancing GC automation.

The GC-9A marked a significant milestone in the integration of mass spectrometry (MS) with capillary gas chromatography (GC). This innovative instrument demonstrated the advantages of using MS vacuum techniques, which thrive on low carrier gas flow rates typical of capillary columns. As a result, it expanded the application fields of gas chromatography significantly.

To enhance its versatility, the GC-9A was equipped with specialized accessories, including the headspace sampler (HS-2A) and advanced injection techniques such as the Cool on Column Injector (OCI-G9) and the furnace pyrolyzer (PYR-2A). These features allowed for a broader range of sample types and improved analytical capabilities.

Additionally, the GC-9A introduced extended temperature programming, accommodating up to five different heating rates. This capability further optimized chromatographic separation, allowing for more precise analysis of complex mixtures.

With the GC-14A, Shimadzu advanced capillary column operation, achieving better sensitivity and chromatographic resolution through newly designed detectors. High-temperature chromatography expanded application ranges, allowing for faster measurements. The modular design of injectors and detectors enables flexible use, accommodating various applications with a single GC system.

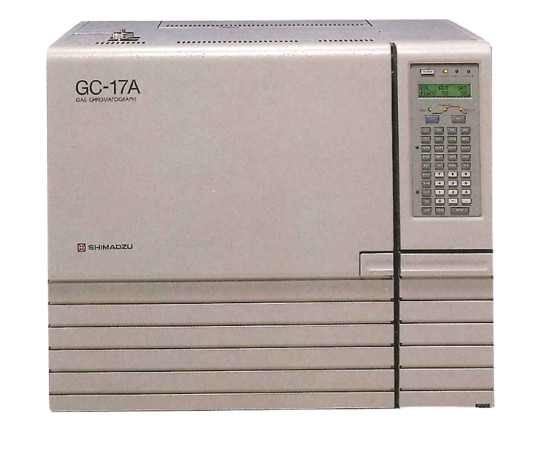

The GC-17A introduced two major innovations: Shimadzu’s Advanced Flow Control (AFC) and Electronic Pneumatic Control (EPC, developed with Hewlett Packard Enterprise, now Agilent Technologies). These features enable electronic control of pressure and split flow for adapting carrier gas flow to the oven temperature program. This maintains a constant average linear velocity over the capillary column, optimizing chromatographic resolution based on the Van Deemter equation.

The GC-2010 set a new standard in precision and sensitivity, featuring numerous innovations that enhance efficiency through high sample throughput and faster analytical responses. It supports dual-line operation and is fully compatible with Fast-GC operation. The development of fast-responding detectors allows for the acquisition of sharp signals from high-resolution chromatography, with adjustable detector response via fine-tuning of sampling frequency and filter time constant.

The GC-2014 is a robust system for routine analysis, providing extensive support for all types of GC columns. Its newly developed pneumatics and flexible detectors ensure precise operation with both packed and capillary columns. With a low footprint, multiple automation features, and a sturdy metal housing, it is ideal for online analysis in process control, even in harsh environments.

The GC-2010 Plus further reduces detector noise levels through advanced electronics, enhancing its sensitivity. New diagnostic functionalities and Advanced Flow Technology simplify operation, even with challenging applications. Additionally, faster oven cooling increases efficiency by reducing delays between GC runs.

As a globally active company, Shimadzu is committed to environmental responsibility. The GC-2025 was designed for economical operation, featuring significant reductions in gas and electricity consumption, low operational noise, and a compact footprint. It was the first GC constructed entirely from RoHS-compliant and recyclable materials.

The GC-2010 Plus Tracera featured the innovative Barrier Ionization Discharge Detector (BID). This advanced technology generates a helium plasma that ionizes all components except for helium and neon. The ionized components are subsequently measured using specialized 'kovar alloy' collection electrodes.

This design enables the Tracera to achieve ultra-trace analysis with exceptional long-term stability, making it a reliable choice for laboratories requiring precise and consistent results.

The Nexis GC-2030 was engineered to redefine the chromatography experience, offering best-in-class performance in sensitivity and precision. It effectively meets the increasing demand for alternatives to costly helium as a carrier gas.

Equipped with fast-reacting pneumatics, automated leak checks, and a hydrogen sensor, the GC-2030 ensures safe operation with hydrogen as the carrier gas, providing a cost-effective and appealing solution for operators. Furthermore, the GC-2030 enhances ultra-fast chromatography through rapid oven heating and cooling, utilizing the resolution advantages of hydrogen as well as fast-responding detectors to achieve accurate results.

Laboratory space is at a premium, and in close collaboration with our customers, we recognized the need for more compact GC systems. The GC-2050 embodies the principle of “Compact without Compromise,” being the smallest GC that supports simultaneous dual-line operation with standard capillary columns. This model introduces new analytical features for easier maintenance, automated capillary column conditioning, and a comprehensive Eco Idling function that significantly reduces gas and electricity consumption during idle times

Throughout its 150-year history, Shimadzu has gathered numerous stories that exemplify its role in the advancement of analytical technology. Each narrative reflects the contributions of individuals and the evolution of innovations across various fields. Below, we present some of these stories that highlight key milestones in our journey and the impact they have had.

Long before climate change became a prominent global issue, the European Union actively promoted biofuels such as biodiesel and bioethanol to reduce dependence on fossil fuel imports. This initiative marked the beginning of Shimadzu Europe's commitment to developing solutions for the quality control of biofuels.

In recent years, green hydrogen produced through electrolysis and energy derived from renewable sources has been discussed as promising alternative to fossil fuels. In response, Shimadzu has developed application solutions to meet various needs, ranging from safety control following electrolysis to high-purity assessments for use in fuel cells.

While hydrogen represents the ultimate goal as a primary energy source, we acknowledge that reaching this target will take time. In the meantime, third-generation biofuels derived from the pyrolysis of biomass or plastic recycling can be integrated into petrochemical processes to help reduce the carbon footprint of fuels. In collaboration with Total Energies, Shimadzu Corporation has developed an analytical solution for the selective determination of nitrogen- and oxygen-containing organic compounds in biofuels, as the concentrations of these components must be significantly reduced before biofuels can be incorporated into traditional petrochemical processes.

Are you interested in our GC products? You can explore them up close at various upcoming events. Our experts will be available to answer any questions you may have. We look forward to seeing you there!

Brevis GC-2050

The Shimadzu Brevis GC-2050, inspired by the Latin word for "compact," combines a space-saving design with exceptional analytical performance. Its compact size allows multiple GCs to be placed on a single laboratory table, enabling simultaneous operation of two analytical lines using standard capillary columns.

Nexis GC-2030

In today's environment, results are needed regardless of whether the analyst is working in the laboratory, the office, or from home. With the flexibility to accommodate a variety of applications, the Nexis™ GC-2030 supports the analyst’s procedures beyond the laboratory, at virtually any location.

GC-2010 Pro

The GC-2010 Pro represents a new generation in Routine GC. Fast oven heating and cooling reduces the analysis time and allow high sample throughput. Based on high-end GC technology, it combines easy operation with efficient analysis and excellence in sensitivity and precision.