Brevis™ GC-2050 - Vlastnosti

Gas Chromatograph

Compact without Compromise

-

-

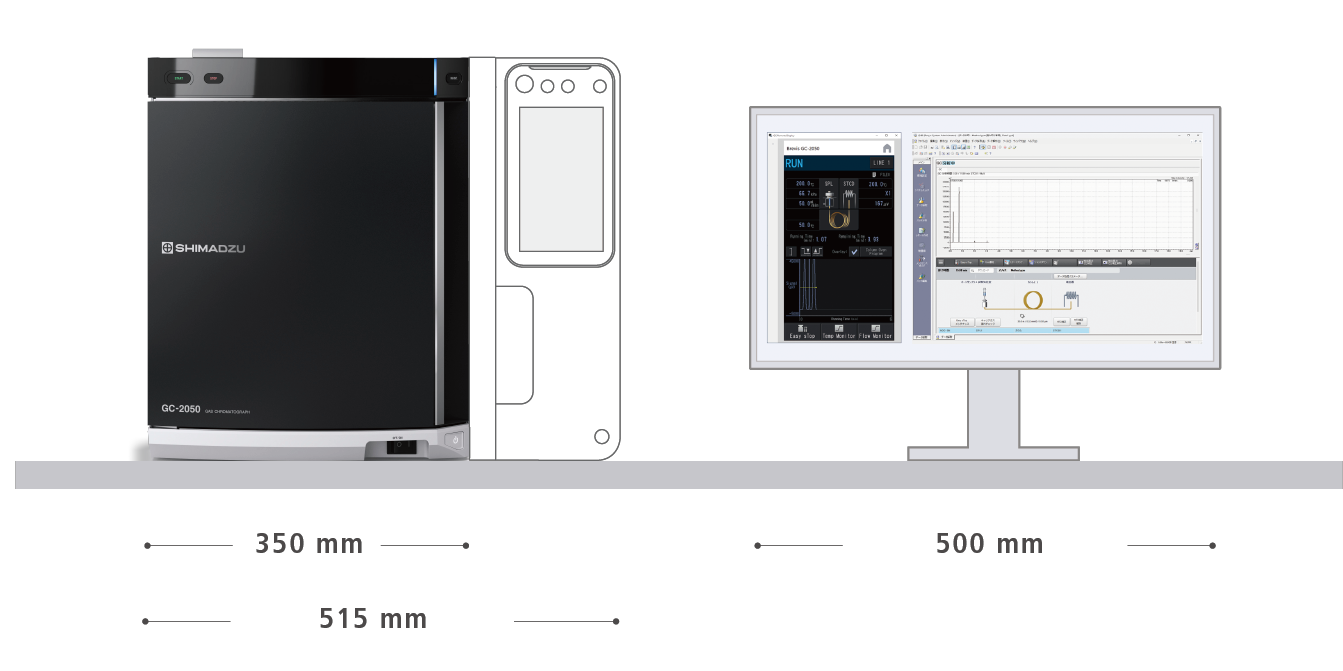

Standard GC with the Width of a Laptop

The Brevis GC-2050 is 350 mm wide, enabling analysis in a space equivalent to a 15-inch laptop. Compared to the flagship Nexis GC-2030, the system's width has been reduced by approximately 35 %. Although the conventional monitoring display has been removed, the GC Remote Display*1 installed on a PC or smart device allows user to check the instrument status and view daily maintenance procedures and videos.

*1: An application for Windows® devices, it can be connected simultaneously with workstations such as LabSolutions.

-

Sufficient Oven Size Fits Two Industry-Standard Columns

Despite Brevis's compact size, the oven is sufficiently large to ensure analysis efficiency. It can accommodate two 7-inch standard capillary columns, enabling simultaneous dual-line analysis.

-

-

-

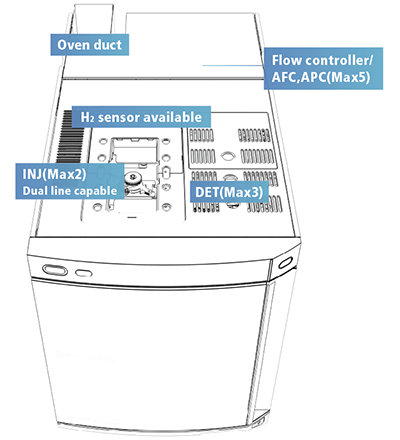

Building on the Established GC Configuration

Built on nearly 70 years of Shimadzu's gas chromatography expertise, the system supports flexible configurations. Easily transition your existing methods and consumables to the Brevis without configuration constraints.

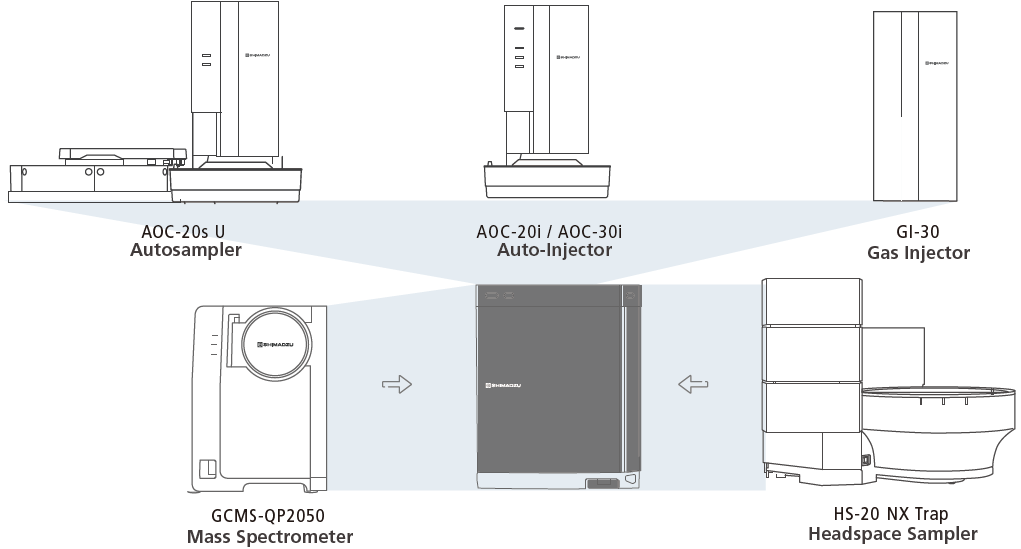

Highly Expandable to Satisfy Laboratory Needs

| Inlet | Columns | Pretreatment Devices |

|---|---|---|

| SPL / WBI / SINJ / PTV / OCI / SPI | 7 inch standard capillary column/packed column | AOC-20 / AOC-30 / GI-30 / HS-20 NX Loop / Trap / HS-10 / AOC-6000 plus / TD-30 / PY -3030D |

| Detectors | Options | Advanced Flow Technology |

|---|---|---|

| FID / TCD / BID / FTD / FPD / ECD / MS | Low temperature control solenoid valve set / Gas selector / Hydrogen sensor / External control relay / Multi position valve |

Detector Splitting (2 detectors, 3 detectors) / BackFlush |

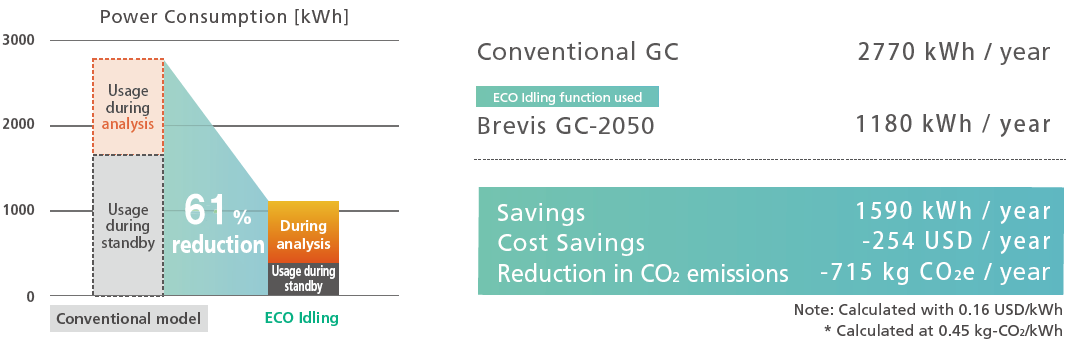

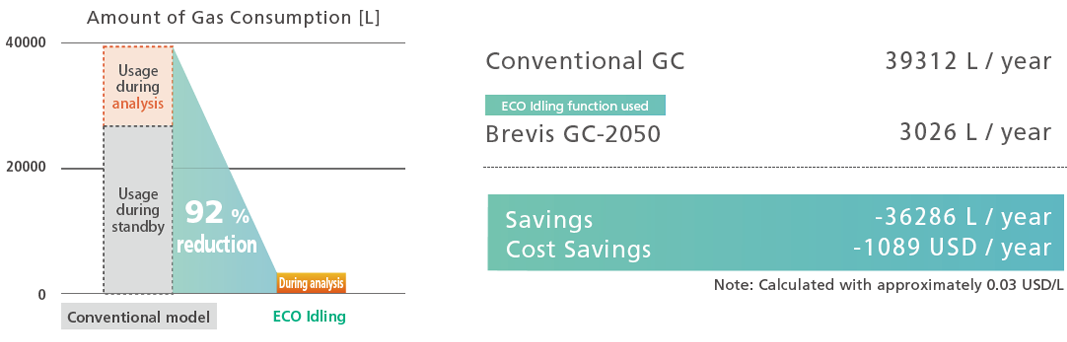

ECO Functions, Less Energy, Less Gas

Running Cost Reductions

The energy-saving design of the Brevis GC-2050 reduces power consumption by 30% compared to conventional models even during normal operation. Furthermore, the new ECO Idling function reduces power consumption by approximately 61% and gas consumption by 92%*2 compared to conventional models. The power saving can be converted into a CO2 reduction equivalent to the annual CO2 absorption of 86 cedar trees per unit*3.

*2 The Eco effectiveness will vary depending on the environment and analytical conditions.

*3: A cedar tree 36-40 years old is estimated to absorb about 8.8 kg of carbon.

This is an estimate of consumption based on 260 days of operation per year with 8 hours of analysis per day, and the instrument in standby when not in use.

Analytical conditions: Column flow rate 2 mL/min, split ratio 50, injector/detector temperature 270°C, oven temperature ramp from 50°C to 250°C at 10°C/min followed by a 10 minute hold. Brevis GC-2050 results were obtained using the ECO idling mode, gas saver and gas selector.

Options Supporting Cost Reductions and Safety

-

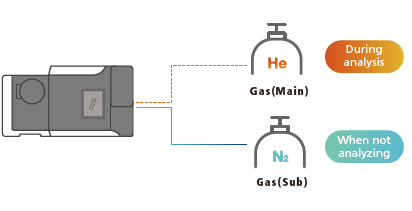

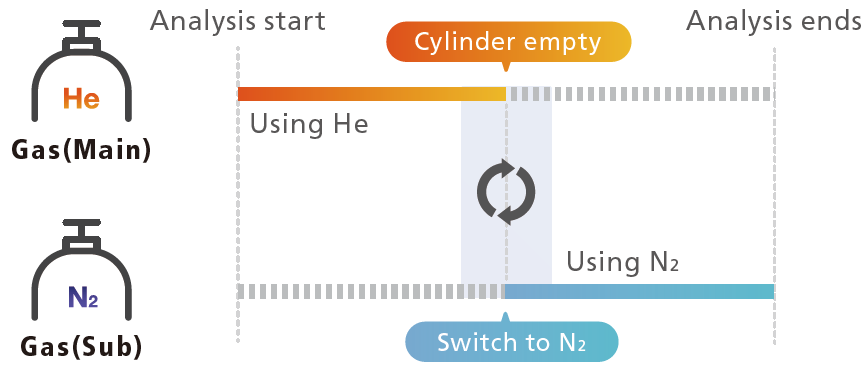

Gas Selector

The carrier gas can be switched from helium to nitrogen except during analysis, therefore minimizing the consumption of helium gas during standby.

-

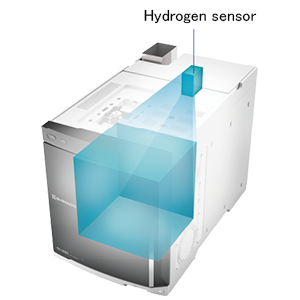

Hydrogen sensor

Analysis can also be performed with easily acquired hydrogen as the carrier gas, thereby maximizing analytical throughput in laboratories with high-speed analyses.

Eco Design

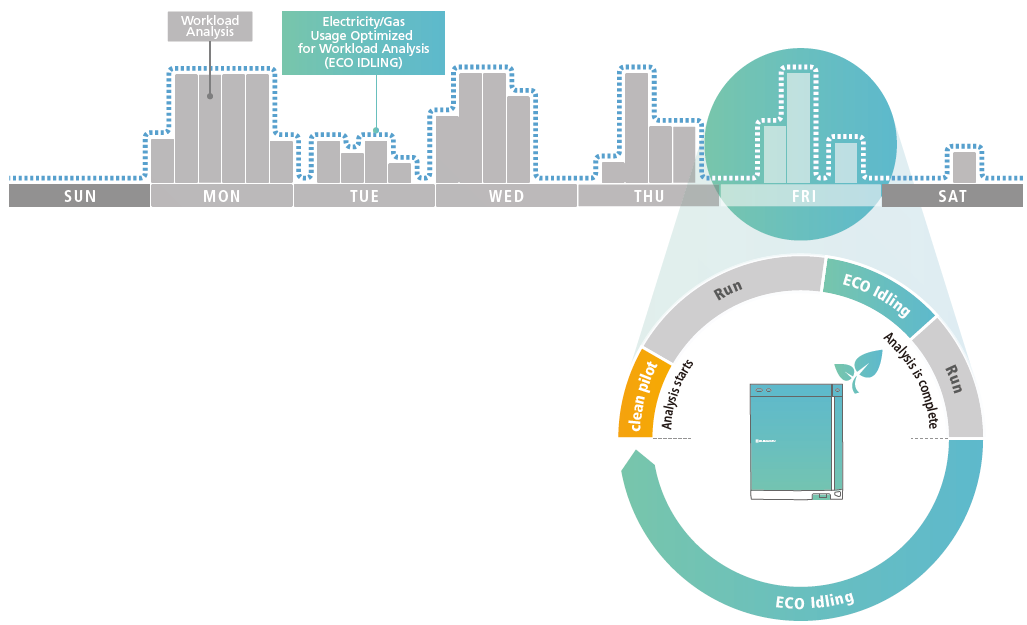

ECO Idling: Making Your Usual Analysis Eco-Friendly

-

ECO Idling Function

The ECO Idling function maintains GC’ s accurate analytical performance as usual during analysis, and automatically switches to an energy-saving status when not analyzing.

It learns the analysis patterns, visualizes the amount of weekly analysis work, and can also propose an eco operation schedule to laboratory chemists. -

-

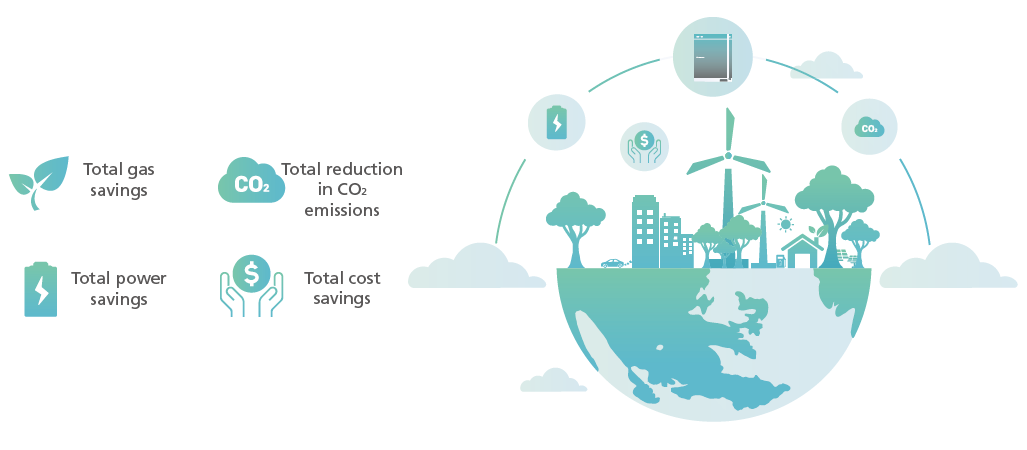

World's First CO2 Reduction Visualizing

Gas Chromatograph*3The amount of of CO2 reduction and power, gas, and cost saved can also be viewed on the software screen which raises operator awareness of savings and makes the lab more eco-friendly.

*3: As of January 2025, according to a Shimadzu survey

-

Built-in Analytical Intelligence

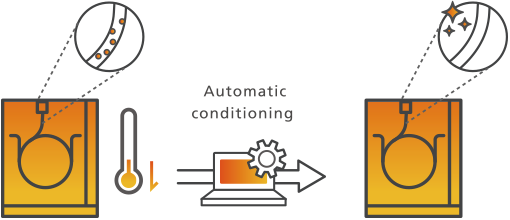

Automating the Procedures of Experienced Analysts, Clean Pilot

-

Baselines can be unstable during GC startup. The Clean Pilot feature provides quick and efficient automatic conditioning to provide stable analytical results while reducing the burden on laboratory personnel.

-

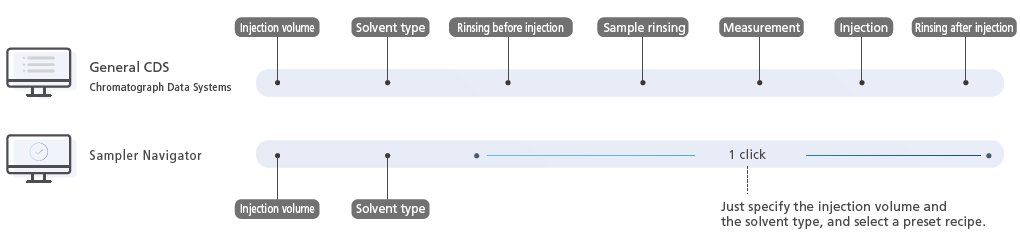

Built-in Injection Expertise, Sampler Navigator

-

Injection may seem trivial, but in reality it is a very complex process that requires a lot of optimization. The Sampler

Navigator reduces the guesswork involved by letting you choose from a carefully curated list of optimized methods, meticulously prepared by experts in gas chromatography. Get up and running with a single click.

Supply Gas Check

-

When connecting a main and a spare gas cylinder to the gas selector (option), the gas selector will monitor the main gas cylinder pressure and automatically switch the gas supply to the backup line when the cylinder becomes empty. This prevents problems before they occur and allows you to continue analysis with peace of mind.

-

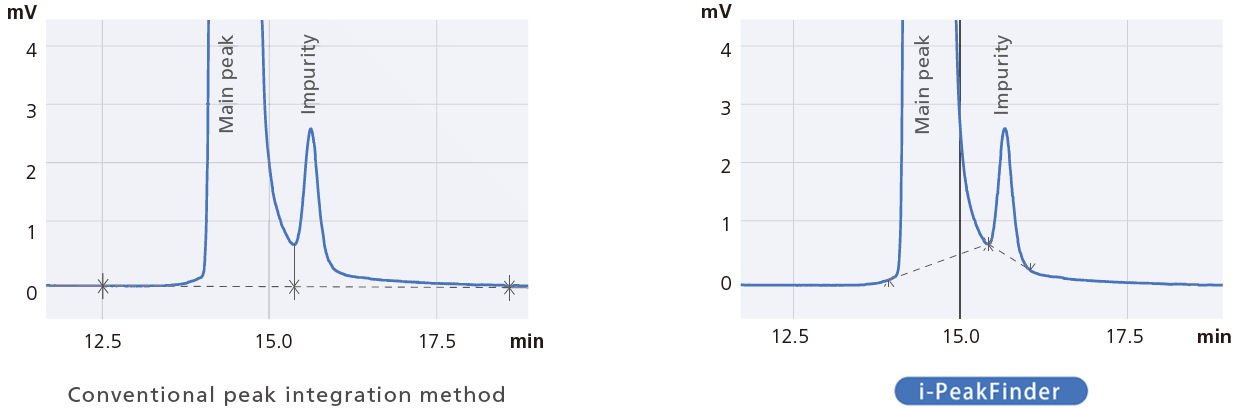

High Precision Data Processing in a Single Step

-

i-PeakFinder Automatic Peak Integration Function

- The manual integration of unresolved peaks is a labor-intensive process prone to inconsistent results depending

upon the experience level of the user. Shimadzu’s proprietary i-PeakFinder peak integration algorithm is perfect for

such situations. i-PeakFinder processes large volumes of data with high precision in a single step, saving time and

increasing the consistency of results.

Easier, Faster, Expert-Level Maintenance

1. One-touch inlet maintenance

The injection port can be opened or closed without tools by simply sliding the ClickTek™ Nut lever. Replace the insert, slide the lever, and feel the click to ensure leak-free performance.

-

2. Fast inlet maintenance, Easy sTop

Clicking the Maint. (Maintenance) button on the GC front will start lowering the temperature of the GC inlet and oven, and stop the gas supply automatically*4. After maintenance of the inlet, clicking the button again will return the instrument to standby after an automatic leak check. Routine maintenance procedures can be further simplified.

*4: Disabling the automatic gas supply shutdown to protect the MS detector is possible.

-

3. Tool-less column installation

The ClickTek makes column attachment a one-touch operation. A noticeable clicking sensation signals a secure column connection, putting the user at ease.

Note: The ClickTek connector is optional.

-

-

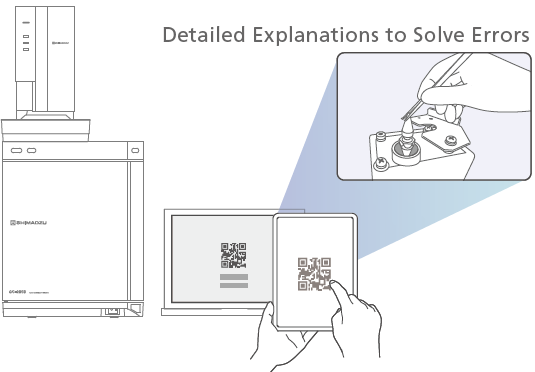

Error Solution Navigation

When a smart device reads the code or clicks the URL link on a PC, a solution, including procedures or videos, is presented for a quick recovery.

-

Remote Operation and Monitoring

LabSolutions Direct, a standard feature of LabSolutions, allows you to monitor instrument status and chromatographic signals, start and stop the instrument, and start the analysis from a web browser on a PC or smart device at a remote location.

-

-

-

Early Detection of Malfunctions

You can remotely monitor the system’s operational status. The early detection of errors or miscues prevents downtime and eliminates valuable sample loss.

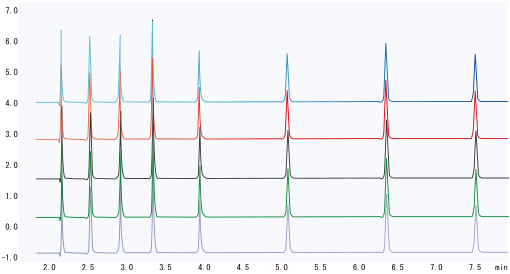

Best-in-Class Performance

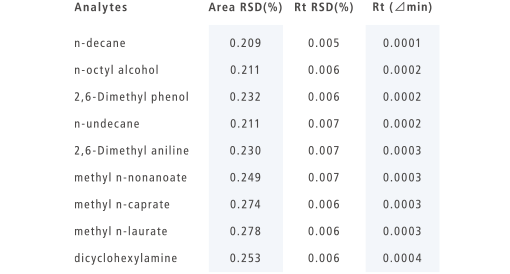

Outstanding Analytical Reproducibility

The Brevis GC-2050 provides best-in-class analytical precision. The latest auto-injector, AOC-30i, enables continuous analysis with a high level of precision that cannot be achieved with manual operation. In addition, the flow controller (AFC) with a built-in CPU supports constant linear velocity, constant flow rate, and constant pressure control of carrier gas to achieve outstanding analytical reproducibility with ultra-high speed and ultra-precise control.

-

- Continuous analysis of the Grob Test Mixture

-